Manufacturing Services

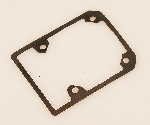

Water Only Jet Cutting - Provides cutting capabilities those items that will not tolerate high pressure, heat, abrasives, or high amounts of water. This process is great for paper, wood, gaskets, rubber, foam, cloth, plastic, an many more items. More

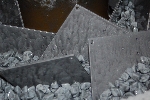

Abrasive Water Jet Cutting - Provides a extremely erosive process under extreme pressure allowing many ferrous and no ferrous materials to be pierced and cut. This Process provides a smooth to rough finish depending on the rate of travel and can also hold relatively tight tolerances. More

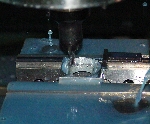

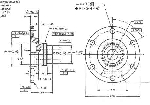

CNC Milling - Provides a extremely tight tolerance and excellent surface finish depending speeds and feeds. This Process can be used to create three dimensional 3-D parts and geometry. The part is generally in a fixed location and the tool and table move generating the desired shape.More

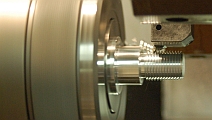

CNC Turning - Provides a extremely tight tolerance and excellent surface finish depending speeds and feeds. This Process can be used to create three dimensional 3-D parts and geometry. The parts spins and the tools move to create the desired shape.More

Fabrication - Provides a assembly of or complete product that is comprised of many items or parts. Fabrication can and will utilize many or all of the services provided by JDA to complete a project.More

Forming / Bending - Provides a unique shape from a flat piece of material. Generally forming or bending a part is done to generate strength or to create a shape to conform to another shape.More

Mig & Tig Welding - Provides a union or permanent bond between two materials. Electricity is passes through the material and can be bonded by fusion or the use of additional filler to create a bond that should be stronger then the original material.More

Vibratory De-Burring - Provides a uniform feel and texture on material or parts relieving the corners and sharp edges. Vibratory Tumbling also will remove scale and rust from ferrous material resulting in a clean smooth part.More

Sawing & Slitting - Provides a service to equally separate solid material from rounds, bar-stock, flat sheet and plate. To accomplish this a conventional horizontal or vertical saw can part the material off. Over the years many metal service centers have used JDA to cut plate sheets and bar stock with our water jets rather then a plate saw.More

Engineering & Design - Will help with product design & development, function, Cad Blue Prints, Cam Programming and Reverse Engineering.More