Forming Bending & Rolling

Forming, Rolling and Bending - Provides a unique shape from a flat piece of material. Generally forming or bending a part is done to generate strength or to create a shape to conform to another shape. Forming is when you are trying to mold or simulate a shape and can be done by roll, brake or some other form of tool to deform the flat material into shape. Dies and presses generate a concentrated force on the material which will result in a bend, crease or shape in the geometry of the tool. Multiple tools or combination of tools may provide a compound bend or form. Rolling a material will create a round flowing part which is great for large rounds or diameters which would be hard to create with a press brake or die.

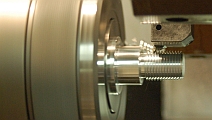

Capacities - JDA has the capability bend, roll and form Steel, Stainless, Aluminum and other materials with brakes, dies and slip rolling equipment. JDA also can create 3-D dies or molds to replicate complex shapes or designs. JDA can Slip roll up to 48" wide with about a minimum of 4-6" diameter depending on the thickness of the material. Bending thickness will vary depending on the width and type of material.

What Types of Materials Steels, Stainless Steels, Aluminum, Plastic, Copper, Brass and other materials have been bent or rolled. There are certain grades of steel, stainless and aluminum the are not practical to bend and may fatigue or crack during the bending process.

Who uses Bending & Rolling - Many industries and individuals have used JDA in the past. Virtually any where you look you have and can see something that has been bent, rolled or formed in some way. Our goal is to help eliminate going to multiple shops to get a complete part. Allowing us to fabricate a part on the waterjet then complete the part by rolling or forming the shape will save time and money in the long run.