Abrasive Water Jet Cutting

Abrasive Water Jet Cutting - Provides a extremely erosive process under extreme pressure allowing many ferrous and no ferrous materials to be pierced and cut. This Process provides a smooth to rough finish depending on the rate of travel and can also hold relatively tight tolerances. Abrasive water jet cutting can be used on almost any material including laminates, glass, plastics and high density rubber. Over the past two decades JDA has cut all of those tricky materials that most shops to not want to attempt.

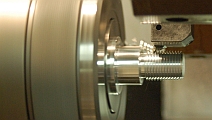

Capacities - JDA has the capability to cut up to 9" thick solid stainless steel down to .0005" shim stock. Sheet sizes can range a dime to 72" x 120" in one setup without having to move the part. Tolerances will range depending on the material, thickness and quality of cut desired. Typical tolerances will range from +-.003" to standard machining tolerances of +-.015". Our typical cutting pressure will be about 50,000-55,000 PSI and will vary depending on the type of cutting we are doing. Fixturing is usually not a issue with water jet cutting but with a full machine shop at our disposal even those little single parts can be cut.

High Yield Nesting JDA Values the customers materials as much as our own. Any material you send JDA to cut we will treat it as our. Why pay more money then you should? JDA does not like to waste material so we take pride in how we nest our parts and jobs to save you money.

Who uses Abrasive Water Jet Cutting - Many industries and individuals have used JDA in the past. From parts for the space program, military and aviation to museum exhibits, displays and attractions JDA has taken a part in help produce the parts they need. Chicago Land Indy and other race teams have used our services to make their cars go, stop and function. Machine Shops will utilize the technology to help reduce time and tool consumption by letting us blank or rough out desired parts allowing them for ease in machining and better material yields.